Manufacturing the Future of Motion

Precision NdFeB Magnets for Smarter Motors & Cleaner Energy

Hello, I’m Dylan Kui

OEM Solutions Expert | Rare Earth Materials Engineer | Elementor Enthusiast

As the Overseas Sales Engineer at Anhui Hanhai New Materials, I bridge cutting-edge NdFeB magnet technology with global industrial applications. While our official website showcases corporate milestones, I built this platform to go beyond brochures – because understanding the science behind the magnet transforms how you engineer with it.

Here, you’ll discover:

🔬 Raw to Ready – Witness how rare earth metals become precision magnets through our ISO-certified/IATF 16949 production line

📊 Grade Deep Dives – Compare Br/Hcj trade-offs for your specific motor design

⚡ Application Spotlights – From traction motor to wind turbine, why NdFeB magnet matters?

🧪 QA That Matters – How we achieve <0.1% batch variance with AI-powered microscopy

Why follow along?

Because whether you’re sourcing for EV traction motors or prototyping a magnetic coupler, the right magnet knowledge saves 12-18% in material costs. Let’s decode the periodic table together.

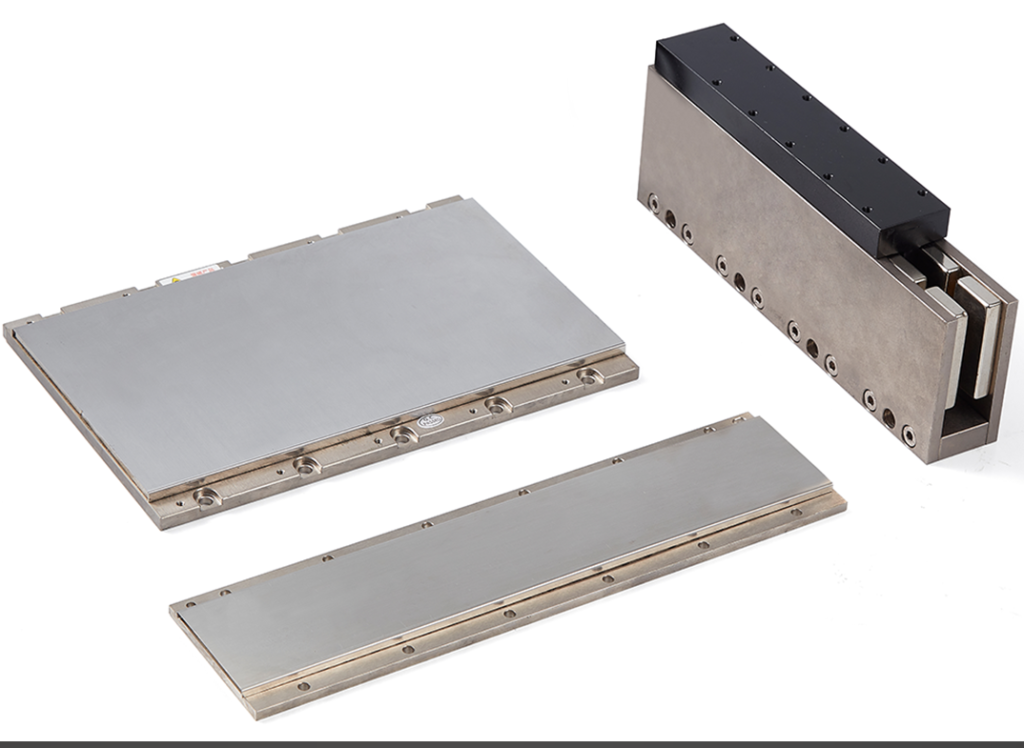

NdFeB Manufacturing Process

Hanhai New Materials is a leading vertically-integrated manufacturer specializing in high-performance neodymium iron boron (NdFeB) permanent magnets. With complete in-house production capabilities spanning the entire value chain – from precision alloy melting and powder metallurgy to magnetic pressing, vacuum sintering, precision machining, and advanced electroplating – we maintain stringent quality control at every manufacturing stage.

Our state-of-the-art facilities incorporate cutting-edge melting technologies and automated production lines to ensure consistent material properties and dimensional accuracy. Through proprietary process innovations, we achieve superior magnetic characteristics including high energy product, excellent temperature stability, and reliable corrosion resistance in our NdFeB products. The company’s integrated manufacturing approach enables tight control over critical parameters from raw material composition to final coating applications.

Permanent Magnet Application

Permanent magnets, particularly high-performance neodymium iron boron (NdFeB) magnets, have become indispensable in modern technology due to their exceptional magnetic strength, compact size, and energy efficiency. These advanced materials power a vast array of applications that touch nearly every aspect of daily life and industrial operations. In consumer electronics, NdFeB magnets enable critical functions in smartphones, headphones, and home appliances, from vibration motors to speaker drivers. The automotive industry relies on them for electric vehicle traction motors, power steering systems, and sensors, while renewable energy applications like wind turbine generators benefit from their high efficiency and reliability. Industrial automation utilizes these magnets in servo motors, robotics, and precision equipment, and even everyday items like magnetic closures on bags and accessories incorporate NdFeB for their strong yet compact magnetic properties. From large-scale power generation to miniature consumer devices, NdFeB magnets continue to drive innovation across industries by delivering superior magnetic performance in increasingly compact and efficient designs.

One of our esteemed magnetics mentors once said: ‘The essence of magnetics lies in studying and continuously optimizing the hysteresis loop of materials – an engineering art.’

At Hanhai, we embody this philosophy: You bring the innovative magnetic application IDEAS, we master the precise MANIPULATION of magnetic properties.

Let’s collaborate to ‘sculpt’ the perfect B-H curve, transforming your concepts into optimally engineered magnetic solutions.

Our Commitment

We take pride as a top tier NdFeB magnet supplier, focusing on our customers’ requirements, and present and future needs, while meeting applicable standards and regulatory requirements.

Quality

Delivering NdFeB magnet thatmeets customer specifications

Service

Providing expert technical supportduring design and production

Support

Dedicated SME consultations for high-grade magnet applications

Excellence

Relentless innovation in rare-earth magnet technology leadership