NdFeB Magnet Press Process

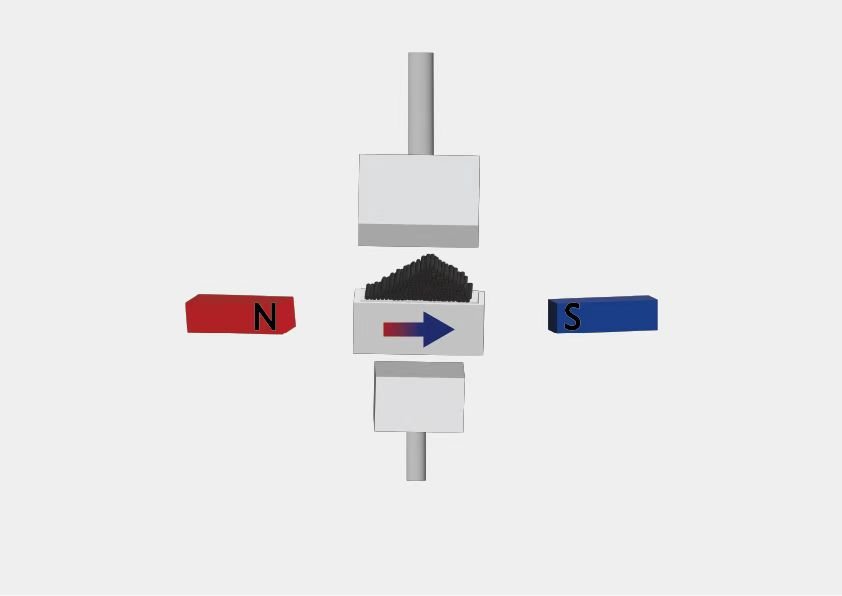

Magnetic Oriented Pressing

In NdFeB magnet production, oriented pressing is the critical powder compaction step. Micron-sized NdFeB powder from jet milling is loaded into a die and aligned under a strong DC magnetic field (1.5-3T) to orient the easy magnetization axes (c-axes) of particles. Subsequent uniaxial mechanical pressing (100-300MPa) forms a green compact with 50-60% theoretical density. This process achieves >95% alignment degree, which is essential for producing anisotropic magnets with superior magnetic properties (Br, Hcj) compared to isotropic versions. Key parameters include field strength (affecting alignment) and pressure (determining density).

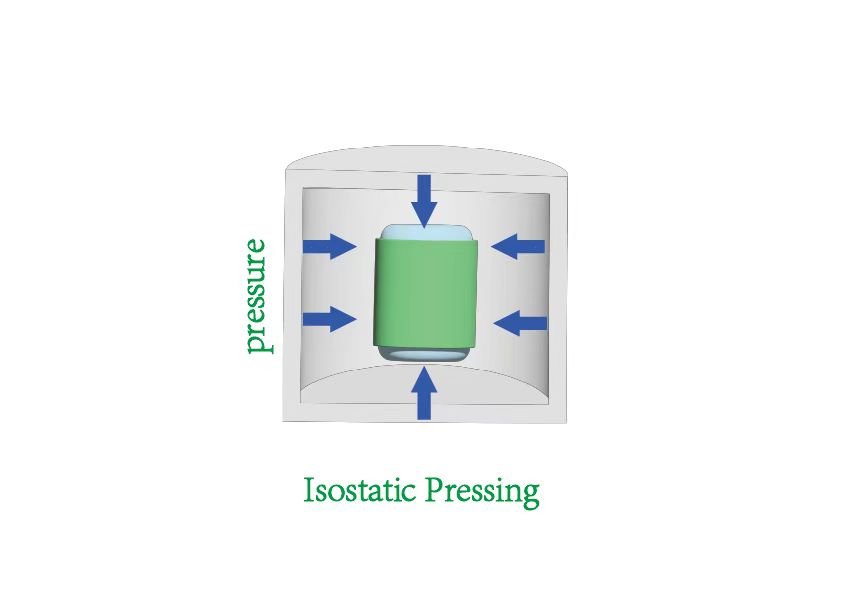

Isostatic Pressing

Isostatic pressing, primarily Cold Isostatic Pressing (CIP at 100-300MPa, room temperature), further enhances compact density (65-75% theoretical) and uniformity. The green compact is subjected to hydrostatic pressure through liquid media (oil/water), eliminating density gradients from oriented pressing and improving microstructural homogeneity. While Hot Isostatic Pressing (HIP) is used for post-sintering densification, CIP is more cost-effective for NdFeB. This process crucially impacts final magnet mechanical strength and magnetic consistency by reducing sintering defects like cracks and distortion.

The synergy between these processes – orientation from pressing and density/homogeneity from isostatic compaction – enables production of high-performance sintered NdFeB magnets.